Caterpillar 313F Track Pads

$72.50 – $115.00Price range: $72.50 through $115.00

-

Minimum Order Quantity: 15 Rubber Track Pads

Please verify product fitment before purchasing.

*GeoGrip mounting bolts not included.

*MT-Pad mounting bolts included.

FREE SHIPPING to commercial addresses!

Caterpillar 313F Rubber Track Pads

Engineered for Caterpillar 313F Excavators, our versatile rubber track pads come in both bolt-on and clip-on configurations. Designed to protect sensitive surfaces while maintaining optimal machine performance, these track pads offer a flexible solution for contractors and operators who require surface-sensitive mobility without compromising equipment capabilities.

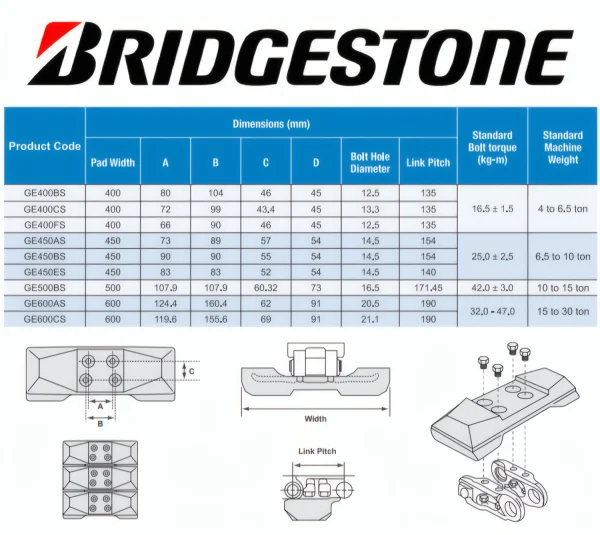

Bridgestone GeoGrip Rubber Tracks Pads for Excavators

Bridgestone GeoGrip rubber pads are individually vulcanized with integrated steel core metals. They bolt directly to the track chain links, providing surface protection without sacrificing durability. Engineered with Bridgestone’s advanced Pro-Edge™ technology, these pads withstand the rigors of construction environments while preventing damage to finished surfaces.

GeoGrip Features & Advantages

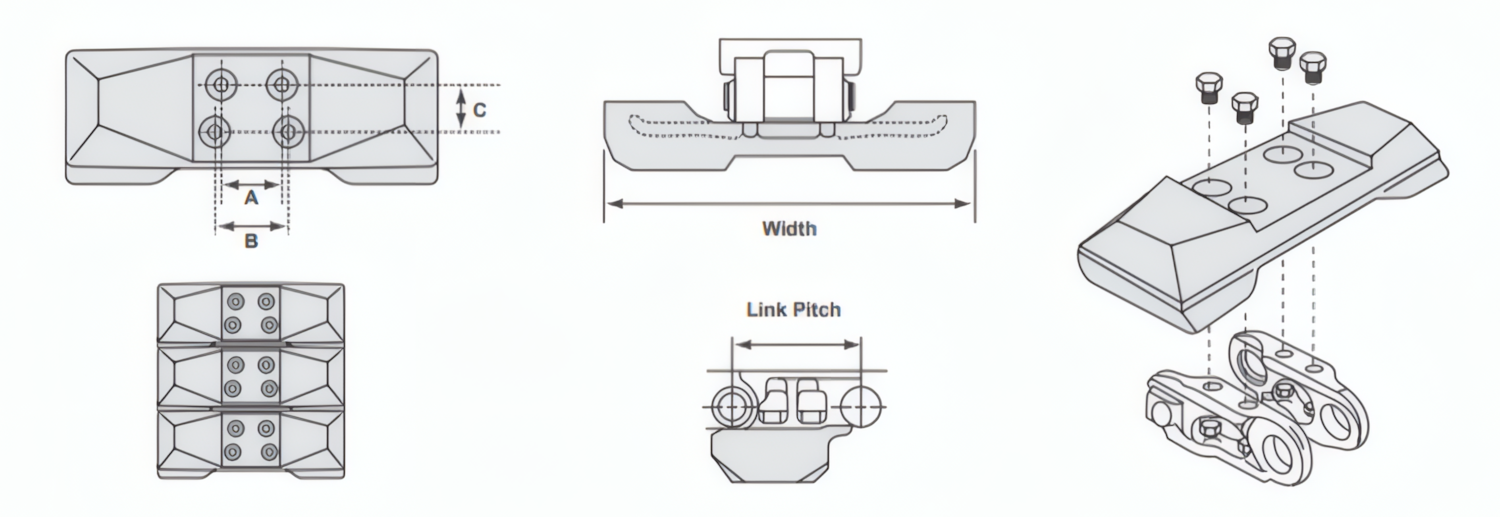

- Quick-Mount Design: Four-bolt installation system attaches directly to track chain links (*mounting bolts not included)

- Pro-Edge™ Technology: Advanced rounded wing profile with tapered tread design disperses impact stress, preventing edge cuts from curbs and obstacles

- Premium Rubber Compound: Super abrasion-resistant formula with Anti-external-cut and anti-chunking properties for extended durability

- Interlocking Design: Unique pad-to-pad interface prevents debris and material buildup in the undercarriage, reducing premature wear and damage

- Forged Core Metals: Specially treated steel provides exceptional strength and wear resistance

- Superior Metal-to-Rubber Bonding: Embedded core metals specially treated to ensure superior adhesion during vulcanization process

GeoGrip Jobsite Benefits

- Surface Protection: Eliminates damage to asphalt, concrete, and finished surfaces that steel tracks would destroy

- Reduced Noise & Vibration: Significantly reduced vibration and noise levels for quieter operation in residential areas and noise-sensitive projects

- Reduced Maintenance: Individual pad replacement capability minimizes downtime and maintenance costs

- Superior Traction: Optimized tread pattern maintains excellent grip and machine stability

- Extended Service Life: Thick rubber volume and specialized compound deliver longer operating life than conventional pads

Caterpillar 313F GeoGrip Rubber Track Pad Size(s) & Specs:

| Product Code | Part # | Pad Weight (lbs) | Pad Width (mm) | A (mm) | B (mm) | C (mm) | D (mm) | Bolt Hole diameter (mm) | Link Pitch (mm) |

|---|---|---|---|---|---|---|---|---|---|

| GE500BS | PAD7560 | 24 | 500 | 107.9 | 107.9 | 60.32 | 73 | 16.5 | 171.45 |

| Standard Bolt torque (kg-m) | Standard Machine Weight | ||||||||

| 42.0 ± 3.0 | 10 to 15 tons | ||||||||

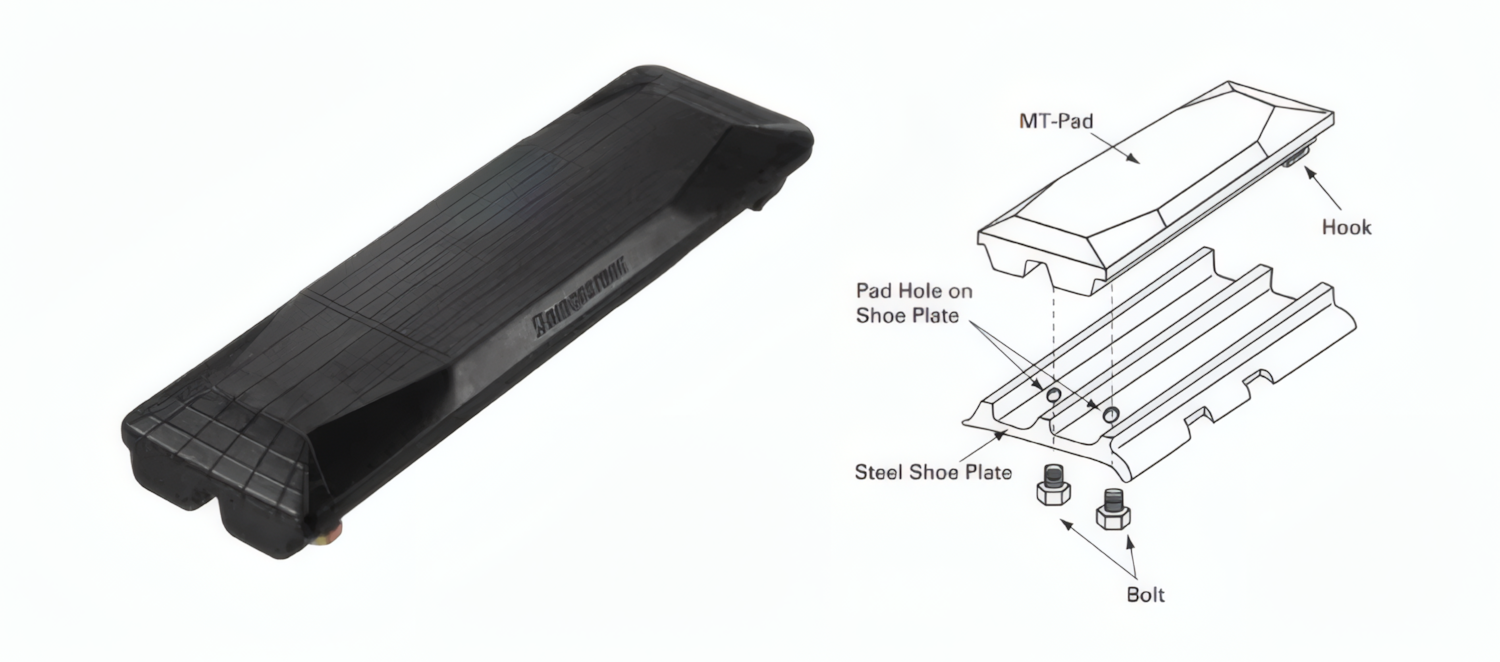

Bridgestone MT-Pad — Rubber Tracks Pads for Excavators

Bridgestone MT-Pads transform aggressive steel tracks into surface-friendly rubber tracks. These pads mount directly over existing steel shoes via a patented clip system, making them the perfect solution for heavy excavators on sensitive surfaces. Bridgestone’s proprietary rubber compound is proven to outlast competing brands by up to 5X.

MT-Pad Features & Advantages

- Single-Side Hook Design: Patented clip system secures to the inner edge of steel shoes for quick, one-person installation (*side/bottom mounting bolts included)

- Optimized Tread Profile: Specifically designed to reduce impact shock while maintaining excellent traction and machine stability

- Superior Durability: Bridgestone’s proprietary anti-cut, anti-chunking proprietary premium rubber compound proven in independent wear testing to significantly outperform competing brands

- Full Coverage Protection: Completely encapsulates steel shoes to prevent any metal-to-surface contact

- Forged Core Metals: Specially treated steel provides exceptional strength and wear resistance

- Reinforced Construction: Multiple internal steel plates treated with high-quality bonding agents during vulcanization for maximum structural integrity

MT-Pad Jobsite Benefits

- Surface Protection: Eliminates damage to asphalt, concrete, and finished surfaces that steel tracks would destroy

- Reduced Noise & Vibration: Significant reduction in track noise for residential and noise-sensitive projects with decreased vibration transmission to the cab during operation

- Reduced Maintenance: Individual pad replacement capability minimizes downtime and maintenance costs

- Faster Installation: Up to 75% quicker mounting time compared to traditional 4-bolt systems

- Enhanced Safety: Eliminates the need for workers to position themselves underneath the machine during installation

- Extended Service Life: Bridgestone’s proprietary specialized rubber compound deliver longer operating life than competing pads

Caterpillar 313F MT-Pad Size(s) & Specs:

| Product Code | Part # | Pad Weight (lbs) | Pad Width (mm) | Bolting Type | Standard Machine Weight |

|---|---|---|---|---|---|

| MT500BS0A | PAD7130 | 14 | 500 | Bottom Bolting | 10 to 15 tons |

Applications

Ideal for utility contractors, municipal work, urban construction, road maintenance, landscaping projects, and any application requiring excavator operation on finished surfaces or sensitive ground conditions.

Quality Assurance

Built with Bridgestone’s industry-leading rubber technology and backed by decades of engineering experience in the construction equipment market. Each pad undergoes rigorous quality control to ensure consistent performance and durability in the field.

Certification: ISO:9001:2000 and ISO:14001 certified manufacturing facilities.

*Please contact our equipment specialists for detailed compatibility verification with your specific machine model and undercarriage configuration.

Related products

-

Caterpillar 305SR Track Pads

$80.00Minimum Order Quantity: 15 Rubber Track Pads

Please verify product fitment before purchasing.

*Mounting bolts not included.

FREE SHIPPING to commercial addresses!-

ADD TO CART -

Caterpillar 307B Track Pads

$85.00Minimum Order Quantity: 15 Rubber Track Pads

Please verify product fitment before purchasing.

*Mounting bolts not included.

FREE SHIPPING to commercial addresses!-

ADD TO CART -

Caterpillar 320D Track Pads

$175.00Minimum Order Quantity: 15 Rubber Track Pads

Please verify product fitment before purchasing.

*Mounting bolts not included.

FREE SHIPPING to commercial addresses!-

ADD TO CART -

Caterpillar 311B Track Pads

$72.50 – $76.95Price range: $72.50 through $76.95Minimum Order Quantity: 15 Rubber Track Pads

Please verify product fitment before purchasing.

*GeoGrip mounting bolts not included.

*MT-Pad mounting bolts included.

FREE SHIPPING to commercial addresses!-

ADD TO CART